3D Animation Preview

| More information about the 3D animation,please |

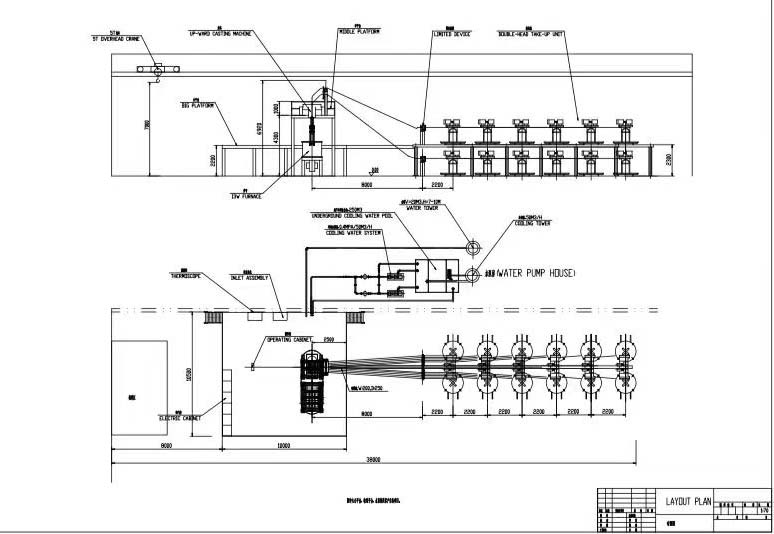

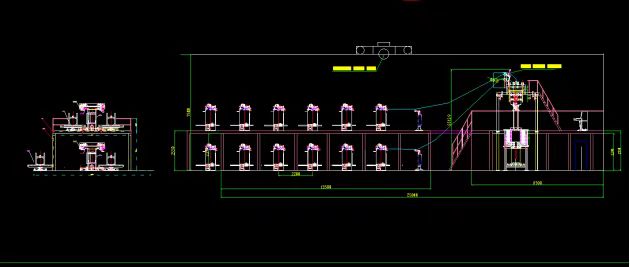

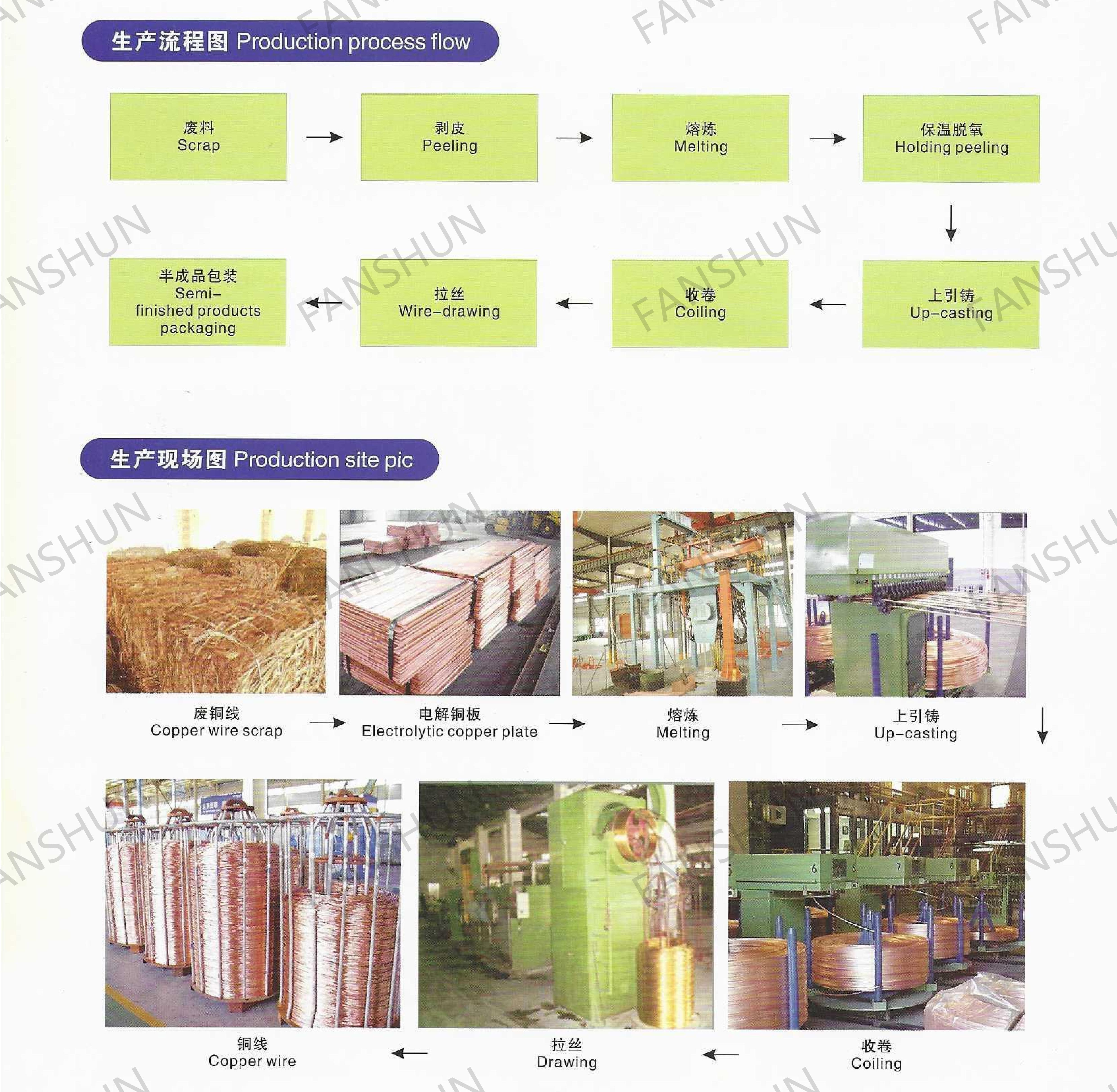

The 200T Oxygen-Free Phosphor Copper Rod Upcasting process represents a significant advancement in copper processing, offering a high-quality method for producing oxygen-free phosphor copper rods that are essential for various industrial applications. This process is integral in creating copper rods that are not only highly conductive but also resistant to oxidation and corrosion. In copper processing, the 200T Oxygen-Free Phosphor Copper Rod Upcasting technique is employed to melt high-purity copper and phosphor alloy in a controlled environment using a sophisticated upcasting furnace. The furnace utilizes advanced technology to ensure precise temperature control and optimal conditions for the casting process. This method allows for the continuous production of copper rods that maintain their copper processing oxygen-free status, crucial for applications requiring superior electrical and thermal conductivity. The Oxygen Free Copper Rod Upcasting process ensures that the final copper rods are free from impurities, which is particularly important when these rods are used in the manufacturing of bronze wire and other high-performance materials. The phosphor content in the rods enhances their mechanical properties, making them suitable for use in various demanding applications. During the casting process, sheet metal straightener ,bronze wire, aluminium alloy,the copper is carefully controlled to avoid oxidation. The result is a high-quality Oxygen Free Copper Rod that exhibits excellent electrical conductivity and durability. This quality is essential for industries that rely on precision components, such as electronics, automotive, and aerospace. The sheet metal straightener is another key component in the copper processing workflow. After the casting process, copper rods may need to be further processed into sheets or other forms. A sheet metal straightener ensures that these metal sheets are free from deformations and meet the required specifications, Oxygen-Free Phosphor Copper Rod Upcasting which is crucial for the subsequent stages of manufacturing and assembly. Additionally, the 200T Oxygen-Free Phosphor Copper Rod Upcasting process supports the production of high-quality materials used in various applications, including aluminium alloy products and bronze wire. The superior quality of the oxygen-free copper rods ensures that they can be used to produce alloys and components with excellent performance characteristics. The primary advantages of the 200T Oxygen-Free Phosphor Copper Rod Upcasting process include its ability to produce rods with minimal oxidation and high purity. This results in improved performance and longevity of the final products. The process also contributes to operational efficiency by allowing continuous casting and reducing waste. sheet metal straightener by integrating advanced technology, this upcasting process ensures that the copper rods meet stringent industry standards and are well-suited for high-demand applications. In summary, the 200T Oxygen-Free Phosphor Copper Rod Upcasting process is a critical technique in copper processing, offering high-quality, oxygen-free copper rods that are essential for producing bronze wire, aluminium alloy components, and other industrial materials. The process Oxygen-Free Phosphor Copper Rod Upcasting enhances the performance and reliability of copper products, ensuring they meet the highest standards of quality and efficiency. |

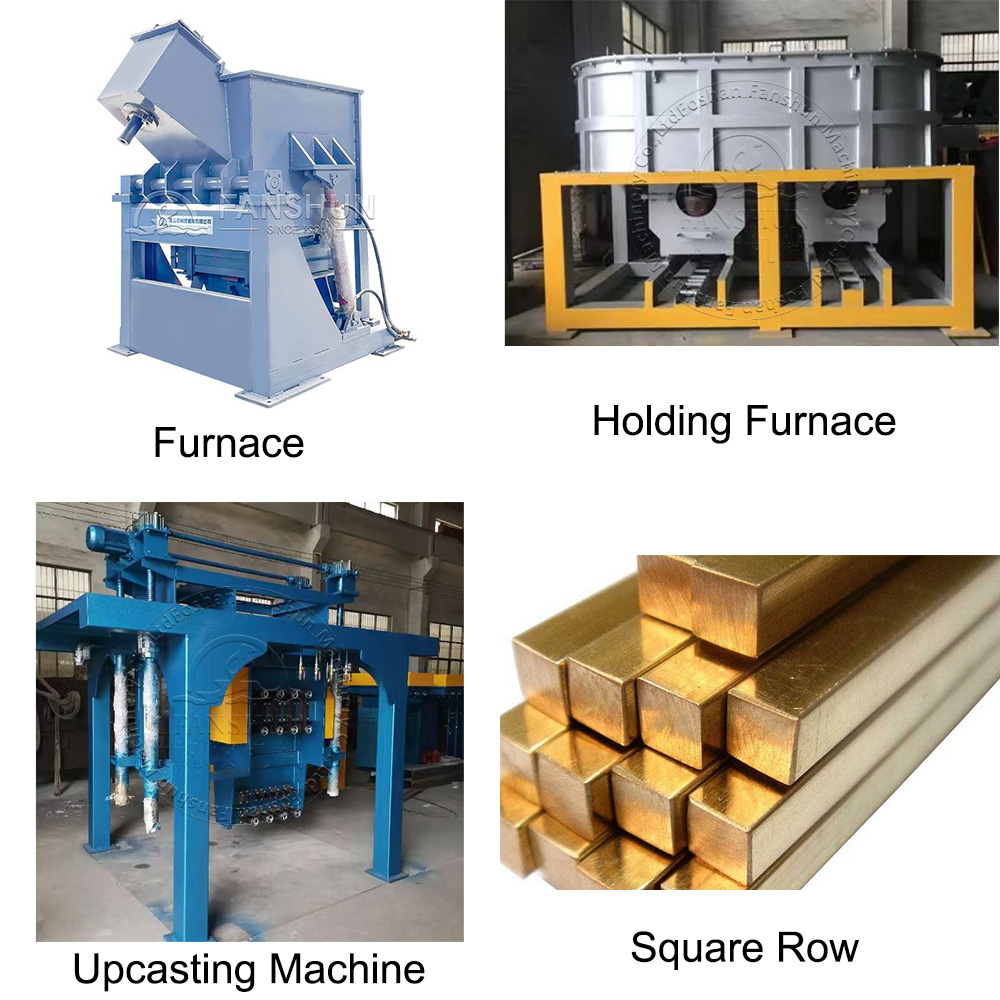

Project Reference Equipment Configuration

| Furnace | Holding Furnace | Up-Casting Machine | Square Row | Pelletising Machine | Environmental Equipment | Cooling System |

120Kw Capacity:2T | 120Kw Capacity:4.5T | 8 heads φ25mm | 100x20mm | 200T 16 granules | 230# Bag 22Kw | Volumn:80T Water Storage:20T |

Equipment Configuration Reference